Introduction

The modern world grapples with an ever-increasing volume of waste, a significant portion of which is composed of plastics designed for durability and longevity.

Conventional plastics, engineered for persistence, accumulate in landfills and natural environments, taking centuries to degrade. This accumulation leads to environmental degradation and poses a serious threat to wildlife. Furthermore, the fragmentation of these plastics results in microplastic pollution, the long-term effects of which on ecosystems and human health are still being understood.

In response to this escalating crisis, biodegradable materials have emerged as a promising alternative, offering a pathway towards a more sustainable future. These materials, designed to be broken down by natural processes, hold the potential to reduce the burden of waste accumulation and mitigate the detrimental impacts of pollution.

This report will look into the science behind biodegradability, exploring the definitions, key characteristics, influencing environmental factors, mechanisms of breakdown, and various categories of these crucial materials.

What Does "Biodegradable" Really Mean? Unpacking the Definitions

The term "biodegradable" is frequently used, but its precise meaning can vary depending on the context and the source. Understanding the core criteria that define a material as biodegradable is essential for both consumers and industries. Environmental science organizations and academic institutions offer several definitions. Generally, biodegradability refers to the ability of microorganisms present in the environment to break down a material.

This process involves the decomposition of the polymer into simpler compounds such as carbon dioxide, water, and nitrogen, which can then be utilized by plants, animals, and other organisms. This decomposition is facilitated by microorganisms like bacteria, fungi, and algae, which convert the material into water, gas, and nutrients, leaving no polluting residue at the end of its lifecycle.

From an academic perspective, biodegradability is the capability of a material to be broken down by living organisms and reabsorbed by the natural environment. These materials are composed of organic compounds containing carbon atoms and can be naturally occurring or human-made. The European Environment Agency (EEA) defines biodegradable as capable of decomposing rapidly by microorganisms under natural aerobic or anaerobic conditions.

Byjus.com offers a similar definition, stating that a biodegradable material can be decomposed by bacteria or other natural organisms without adding to pollution, and this process can be influenced by microbes and abiotic elements like temperature, UV radiation, and oxygen.

Good Start Packaging describes biodegradable products as those that can be consumed by living microorganisms like fungi or bacteria, breaking them down into compounds found in nature.

Government agencies like the Environmental Protection Agency (EPA) also provide definitions. The EPA generally defines biodegradable as the ability of a substance to be broken down physically and/or chemically by microorganisms.

Aerobic biodegradation, a specific type, involves the breakdown of materials into carbon dioxide, water, and other organic materials within months or years. The EPA has also established specific standards for certain product categories.

For environmentally acceptable lubricants and greases, biodegradable means that a certain percentage of the formulation must degrade within a specified timeframe. Similarly, for cleaning products and biocidal substances, biodegradability is defined by the removal of dissolved organic carbon or the production of carbon dioxide within 28 days.

Regarding bioplastics, the EPA notes that they can be engineered to biodegrade into carbon dioxide or methane, water, and biomass over time under certain environmental conditions. The Organisation for Economic Co-operation and Development (OECD) has classified biodegradability into categories based on the rate of breakdown.

"Readily biodegradable" substances must degrade by at least 60% within 28 days under conditions designed to resemble wastewater treatment plants. The OECD also outlines other classifications such as highly, intermediate, and inherently biodegradable based on the extent and timeframe of degradation.

From these definitions, several core criteria consistently emerge. Biodegradability involves the action of microorganisms such as bacteria and fungi. The material is broken down into simpler, naturally occurring substances, including water, carbon dioxide, methane, biomass, and minerals.

A key aspect is the absence of persistent pollution following degradation. While the timeframe for biodegradation varies significantly across different definitions and standards, it remains a crucial factor in determining a material's environmental impact.

It is important to distinguish "biodegradable" from related terms like "compostable" and "degradable." Compostable materials are a subset of biodegradable materials that are required to completely decompose within a specific period under certain conditions, typically found in industrial composting facilities.

For instance, ASTM D6400 defines compostable plastics as those that degrade into water, carbon dioxide, biomass, and inorganic substances through biological action in an industrial composting process within 180 days, leaving no toxic residues. Compostable materials are also expected to enrich the soil with nutrients. The European equivalent standard is EN 13432, which also sets strict criteria for disintegration, biodegradation, absence of negative effects on the composting process, and low levels of heavy metals.

Standards for home compostability, such as Australian standard AS 5810 and French standard NF T51-800, often have more stringent requirements regarding timeframe and temperature. In contrast, "degradable" is a broader term that simply means a material can break down into smaller pieces or molecules over time through various processes, including sunlight, moisture, and oxidation. This term does not necessarily imply complete breakdown by microorganisms into natural substances or within a specific timeframe.

"Oxo-degradable" plastics, which contain additives to accelerate their breakdown in the presence of oxygen and UV light, are a controversial example. While they degrade into smaller fragments, these fragments are often microplastics, leading to environmental concerns and a ban on such plastics in the EU.

The term "biodegradable" is sometimes used ambiguously in marketing, a practice known as "greenwashing". Claims of biodegradability without specific timeframes or environmental conditions can be misleading, as many materials will technically degrade eventually, but over timescales that are environmentally irrelevant.

To ensure that claims of biodegradability are genuine and environmentally beneficial, it is important to look for recognized certifications such as those provided by the Biodegradable Products Institute (BPI) based on ASTM standards, or compliance with standards like ASTM D6400 and EN 13432. These certifications provide a level of assurance that the material will break down under specific conditions within a reasonable timeframe and without harmful effects.

Key Chemical and Structural Characteristics

The ability of a material to biodegrade is fundamentally linked to its chemical composition and structural organization at the molecular level. Certain types of chemical bonds are more susceptible to breakdown by microorganisms and their enzymes.

Polymers containing ester, amide, or ether bonds are generally more biodegradable because these bonds can be cleaved through hydrolysis, a process that is often facilitated by microbial enzymes. Examples of such polymers include polyesters like polylactic acid (PLA), polyhydroxyalkanoates (PHAs), and polycaprolactone (PCL), as well as polyamides and polyurethanes.

In natural polymers like starch and cellulose, the glycosidic bonds linking the sugar units are also susceptible to enzymatic breakdown. In contrast, polymers with carbon-carbon backbones, prevalent in conventional plastics such as polyolefins (e.g., polyethylene and polypropylene), are more resistant to hydrolysis and biodegradation, often requiring an initial oxidation step to facilitate further breakdown.

The presence of specific functional groups, such as hydroxyl and amine groups, can also enhance biodegradability by increasing the material's ability to absorb water and interact with enzymes. Conversely, certain chemical structures, like halogens, chain branching, nitrogen-containing rings, and some ether bonds, can hinder the biodegradation process.

The molecular weight of a polymer plays a significant role in its biodegradability. Polymers with lower molecular weights tend to degrade faster because there are more chain ends available for enzymatic attack, and fewer bonds need to be broken down to achieve complete degradation. For instance, studies on PLA have shown that its marine biodegradability is inversely proportional to its molecular weight; lower degrees of polymerization lead to higher degradation rates.

The physical structure of a polymer, particularly its crystallinity, also influences how readily it can be biodegraded. Amorphous, or non-crystalline, regions of a polymer are more easily accessed by water and enzymes compared to highly ordered crystalline structures, which have a denser packing that hinders microbial access. This is why PLA's crystallinity can sometimes limit its rate of biodegradation.

The balance between a polymer's affinity for water, known as hydrophilicity, and its aversion to water, or hydrophobicity, is another crucial factor. Hydrophilic polymers tend to biodegrade more readily because water facilitates the action of many enzymes and promotes microbial attachment to the material's surface.

However, if the degrading enzymes are water-soluble, highly hydrophobic polymers might hinder their interaction. It's worth noting that some microorganisms and their enzymes have evolved to degrade hydrophobic substrates.

Finally, the surface area of a material significantly affects its biodegradability. A higher surface area provides more sites for microorganisms to colonize and for enzymes to attack the polymer chains, generally leading to faster rates of degradation. For example, thin films of a biodegradable polymer might degrade faster than thicker blocks of the same material due to a higher surface area to volume ratio.

Environmental Conditions That Dictate Degradation

While the intrinsic chemical and structural characteristics of a material determine its potential for biodegradability, the surrounding environmental conditions play an equally vital role in whether and how quickly this potential is realized.

Temperature is a primary environmental factor influencing biodegradation rates. Generally, within the range optimal for microbial activity, higher temperatures accelerate the process by increasing the metabolic rate of microorganisms and the activity of their enzymes.

The Arrhenius law suggests that for plastic degradation, every 10-degree Celsius rise can double the degradation rate. Optimal temperatures for many biodegrading microorganisms fall between 30 and 40°C, but thermophilic microorganisms in composting environments thrive at even higher temperatures, typically between 50 and 70°C.Conversely, extremely low temperatures can significantly slow down or even halt biodegradation due to reduced microbial activity.

For instance, polylactic acid (PLA) requires high temperatures, typically above 55-70°C, for effective biodegradation in industrial composting facilities.

Humidity, or the availability of moisture, is another critical factor. Water is essential for hydrolysis, a key mechanism in the breakdown of many biodegradable polymers, and it also supports microbial growth and the efficiency of enzymatic reactions. Adequate moisture levels in the environment are crucial for the enzymatic reactions that degrade materials. In soil, an optimal moisture content of 50-70% of the water holding capacity generally promotes aerobic biodegradation.

Too much moisture, however, can limit the transfer of oxygen, which is vital for aerobic processes. Conversely, very low humidity can lead to desiccation, hindering microbial activity. The effect of moisture content can also vary depending on the type of polymer, with some synthetic polymers potentially degrading faster at moderate humidity, while natural polymers like cellulose might prefer higher levels.

Oxygen availability plays a crucial role in the type and rate of biodegradation. Aerobic biodegradation, which occurs in the presence of oxygen, is generally faster and results in the production of carbon dioxide, water, and microbial biomass. Oxygen acts as an electron acceptor in the metabolic processes of aerobic microorganisms that break down hydrocarbons and other organic materials.

The availability of oxygen can often be a limiting factor, particularly in subsurface environments and within landfills. Anaerobic biodegradation, which occurs in the absence of oxygen, is typically slower and produces carbon dioxide, methane, water, and biomass.

This type of degradation is important in environments where oxygen is limited, such as landfills and marine sediments. Some materials, like polyhydroxybutyrate (PHB), can be degraded by anaerobic bacteria. Landfill environments, characterized by limited oxygen and high moisture levels, create anaerobic conditions that can slow down the overall decomposition and biodegradation processes.

The presence and activity of specific microbial communities are fundamental to biodegradation. The process is primarily carried out by microorganisms, including bacteria, fungi, and algae, which secrete enzymes capable of breaking down the complex structures of polymers.

The diversity and abundance of these microbial communities in a given environment directly impact the rate and extent of biodegradation. Different types of microorganisms possess different enzymatic capabilities and substrate specificities, meaning that the presence of the right kind of microbes is essential for the effective degradation of a particular material.

For example, certain fungi, such as Aspergillus clavatus and Aspergillus niger, are highly effective at breaking down various biodegradable materials, including some plastics. Changes in environmental conditions, such as those occurring during grassland degradation, can alter the composition of soil bacterial and fungal communities, which in turn can affect nutrient cycling and the degradation of introduced materials.

Microbial consortia, which are communities of different microorganisms working together, can sometimes be more efficient at degrading complex or recalcitrant materials compared to single strains due to their functional stability and broader enzymatic capabilities. In marine environments, microbial communities that colonize the surfaces of plastic debris, known as the "plastisphere," play a significant role in the degradation of plastics, including biodegradable ones.

The Mechanisms of Biodegradation

The breakdown of biodegradable materials by microorganisms occurs through a series of intricate processes, primarily involving enzymatic degradation, hydrolysis, and oxidation. Microorganisms initiate this process by secreting extracellular enzymes into their surroundings.

These enzymes act as biological catalysts, speeding up the breakdown of long polymer chains into smaller fragments such as oligomers, dimers, and monomers. Extracellular enzymes can be classified as either exo-enzymes, which cleave polymer chains at their end groups, or endo-enzymes, which break bonds within the polymer chain.

Various types of hydrolytic enzymes, including hydrolases, esterases, lipases, cutinases, amylases, cellulases, and proteases, are crucial for breaking specific chemical bonds found in different biodegradable polymers. For example, esterases and lipases are involved in the degradation of polyesters like PLA and PHA, while amylases and cellulases break down the glycosidic bonds in starch and cellulose, respectively.

Oxidative enzymes, such as laccases and peroxidases, can play a role in degrading more recalcitrant polymers like polyethylene (PE) and polyvinyl chloride (PVC).The specificity of enzymes means that different enzymes are required to effectively break down different types of polymers.

Hydrolysis is another key mechanism in biodegradation. This chemical process involves the breaking of chemical bonds, particularly ester and amide bonds, through the addition of water.

While hydrolysis can occur spontaneously, it is often catalyzed by microbial enzymes or by acids or bases present in the environment. The rate of hydrolysis is influenced by factors such as the polymer's hydrophilicity and the pH of the surrounding environment. For polymers like PLA, the degradation process typically begins with the hydrolysis of its ester bonds.

Oxidation is also involved in the biodegradation of some materials. This process involves the reaction of the polymer with oxygen or other reactive oxygen species, which can lead to chain scission, crosslinking, or modifications in the polymer's functional groups.

Oxidation can be initiated by various factors, including UV light (photo-oxidation), heat, or the presence of metal ions. This mechanism is particularly important for the degradation of polymers that contain unsaturated bonds or are easily oxidizable, such as polyolefins. For example, oxo-degradable plastics rely on oxidation as a primary step in their breakdown.

The overall process of biodegradation can be broadly divided into three main stages. The first stage is biodeterioration, which involves the initial surface-level degradation of the material. This can be caused by abiotic factors like sunlight, temperature changes, and mechanical stress, as well as the initial colonization by microorganisms.

Biodeterioration results in mechanical weakening of the material and observable changes in its physical and chemical properties, such as discoloration and the formation of cracks. The second stage is biofragmentation, also known as depolymerization.

During this phase, microorganisms excrete enzymes that progressively reduce the molecular weight of the polymer, breaking the long chains into smaller fragments like oligomers, dimers, and monomers. Finally, the third stage is assimilation, also referred to as mineralization. In this step, the smaller molecules produced during biofragmentation are absorbed by the microorganisms into their cells.

The microorganisms then metabolize these molecules as a source of carbon and energy, converting them into carbon dioxide (under aerobic conditions) or methane (under anaerobic conditions), as well as water, biomass, and inorganic salts. Complete biodegradation is said to occur when there are no longer any oligomers or monomers remaining, signifying the full conversion of the original material into these natural byproducts.

Categories of Biodegradable Materials

The realm of biodegradable materials encompasses a wide variety of substances, each with its unique characteristics and applications. One prominent category is bioplastics, which are plastics derived from renewable biomass sources or from fossil resources but engineered to be biodegradable.

Polylactic acid (PLA) is a well-known bioplastic derived from the fermentation of plant sugars like corn starch or sugarcane. PLA is composed of lactic acid monomers linked by ester bonds, which are susceptible to hydrolysis. While PLA is biodegradable, it typically requires specific industrial composting conditions with high temperatures and humidity to break down effectively.

In natural environments, its degradation can be quite slow. PLA finds applications in packaging, disposable tableware, 3D printing, and even medical devices.

Another significant class of bioplastics is polyhydroxyalkanoates (PHAs). These are produced by microorganisms through the fermentation of sugars or lipids. A common type of PHA is polyhydroxybutyrate (PHB). PHAs are notable for their biodegradability across a wide range of environments, including soil, marine, and compost settings.

They often degrade faster than PLA under natural conditions. The versatile properties of PHAs make them suitable for use in packaging, agricultural films, consumer goods, and medical applications.

Starch-based bioplastics are made from starch derived from sources like corn, potatoes, and tapioca. Starch, a polysaccharide composed of amylose and amylopectin, is highly biodegradable due to the enzymatic hydrolysis of its glycosidic bonds. These bioplastics are used in packaging, disposable tableware, and protective packaging and are often blended with other biodegradable polymers to enhance their properties.

Cellulose-based films are another category, made from cellulose, a natural polymer found in plant cell walls. Cellulose, a polysaccharide with β-glycosidic linkages, is inherently biodegradable, although the rate can vary depending on factors like crystallinity and the presence of lignin or chemical modifications. Generally, cellulose is considered less biodegradable than starch. Applications include packaging, films, and textiles like rayon and viscose.

Other notable biodegradable bioplastics include polybutylene succinate (PBS), which can be bio-based or fossil-based and is biodegradable, used in mulching films, packaging, and fibers, and polycaprolactone (PCL), a synthetic aliphatic polyester that is biodegradable through hydrolysis and used in medical applications due to its biocompatibility and gradual degradation.

Beyond bioplastics, several natural polymers exhibit biodegradability. Proteins, such as collagen, gelatin, and wheat gluten, are naturally occurring macromolecules composed of amino acids linked by peptide (amide) bonds, which are susceptible to enzymatic breakdown. Collagen, for instance, is highly biodegradable and is used in medical applications like sutures and tissue engineering, as well as in food packaging.

Chitosan, a biopolymer derived from chitin found in crustacean shells, is a biodegradable polysaccharide with antimicrobial properties, used in food packaging and medicine. Alginate, a polysaccharide derived from brown seaweed, is also biodegradable, non-toxic, and non-inflammatory, finding use in wound dressings and food products.

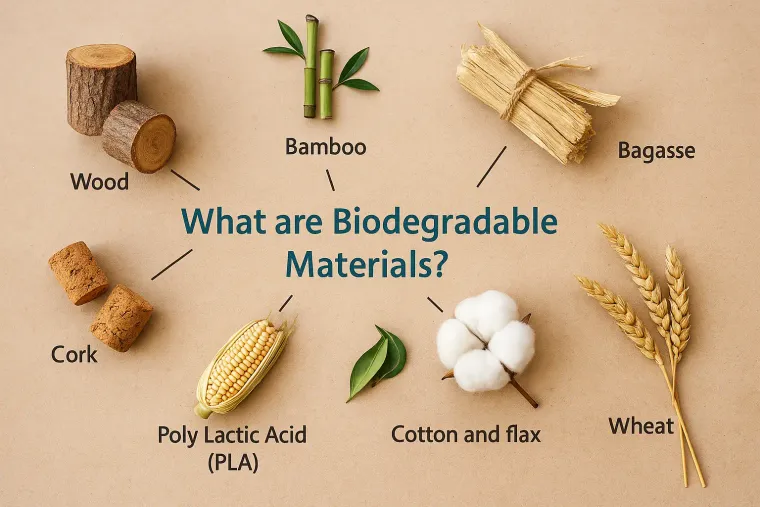

Various other organic materials also demonstrate biodegradability. Bagasse, the residue from sugarcane processing, is biodegradable and used for tableware. Mushroom mycelium, the root-like structure of fungi, is biodegradable and compostable, used for packaging. Seaweed can be used as a biodegradable and sometimes edible packaging material.

Pulp, derived from recycled paper and cardboard, is biodegradable and compostable, used for thermoformed packaging. Palm leaves, naturally fallen, are biodegradable and used for plates and bowls. Cork, hemp, jute, and untreated wood are also examples of naturally biodegradable materials with various applications.

Comparing Biodegradability Across Materials

The biodegradability of different materials varies significantly depending on their chemical structure, physical properties, and the environmental conditions they are exposed to. Starch is generally considered more readily biodegradable than cellulose due to its less crystalline structure and the α-glycosidic linkages in starch, which are more easily hydrolyzed compared to the β-glycosidic linkages in cellulose.

However, the rate of cellulose biodegradation can vary widely depending on its form and the specific environment. When comparing the bioplastics PLA and PHA, PHA is often considered to be more biodegradable, particularly in natural environments such as soil and marine environments, and it can degrade without requiring the high temperatures of industrial composting that PLA typically needs. In fact, PHA often degrades faster than PLA in natural conditions.

Bioplastics, in general, are designed to biodegrade much faster than conventional petroleum-based plastics like polyethylene (PE), polypropylene (PP), and polystyrene (PS), which can persist in the environment for hundreds or even thousands of years.

However, it's crucial to note that the term "biodegradable plastic" can be misleading, as some may only degrade under very specific conditions or may only partially break down.

As discussed earlier, higher molecular weight and higher crystallinity in polymers generally lead to slower rates of biodegradation across various material types. The same material can also exhibit vastly different biodegradation rates depending on the environmental conditions, including temperature, humidity, oxygen availability, and the specific microbial community present.

For instance, biodegradation in soil can differ significantly from that in marine environments or industrial composting facilities. Finally, additives used in both conventional and biodegradable plastics can influence the biodegradation process, sometimes hindering it.

To illustrate the differences in biodegradation rates, the following table provides typical degradation times for various materials under different environmental conditions:

| Material | Environment | Typical Biodegradation Time |

|---|---|---|

| Vegetables | Soil | 5 days – 1 month |

| Paper | Soil | 2–5 months |

| Cotton T-shirt | Soil | 6 months |

| Orange peels | Soil | 6 months |

| Tree leaves | Soil | 1 year |

| Wool socks | Soil | 1–5 years |

| Plastic-coated paper milk cartons | Soil | 5 years |

| Leather shoes | Soil | 25–40 years |

| Nylon fabric | Soil | 30–40 years |

| Tin cans | Soil | 50–100 years |

| Aluminium cans | Soil | 80–100 years |

| Glass bottles | Soil | 1 million years |

| Cigarette butts | Various | 18 months to 10 years |

| Plastic bags | Various | 500 years to forever |

| Styrofoam cup | Various | 500 years to forever |

| PLA | Industrial Compost | 30–60 days |

| PLA | Natural Environments | Potentially hundreds of years |

| PHA | Marine & Terrestrial | A few months |

| Cellulose | Various | Months to years (highly variable) |

This comparison highlights the vast differences in the persistence of various materials and underscores the context-dependent nature of biodegradability.

Challenges and Limitations of Biodegradability

Despite the promise of biodegradable materials, several challenges and limitations are associated with their use. One significant issue is that many biodegradable materials, particularly bioplastics like PLA, require specific environmental conditions to degrade effectively.

For example, PLA often needs the high temperatures found in industrial composting facilities and may not readily break down in typical landfill or natural environments. Another concern is the potential for incomplete degradation, where materials might only partially break down, leaving behind fragments or residues. This can be problematic if these residues are harmful or persist in the environment.

A particularly significant challenge is the formation of microplastics from some biodegradable plastics, especially oxo-degradable plastics, which tend to fragment into tiny plastic particles rather than fully mineralizing. These microplastics can pose a threat to ecosystems and potentially to human health.

While the goal of biodegradation is the breakdown into harmless substances, the ecotoxicity of intermediate or final degradation products also needs consideration. Standards for compostability, such as ASTM D6400 and EN 13432, often include ecotoxicity testing to address this concern.

The introduction of biodegradable plastics can also impact existing recycling infrastructure. These plastics can contaminate conventional plastic recycling streams, potentially lowering the quality of the recycled materials. Therefore, effective management of biodegradable plastics may require the development of separate collection and processing infrastructure, which is not yet widely established in many regions.

The production of some bioplastics relies on agricultural feedstocks, such as corn for PLA, which raises concerns about land use, water consumption, and potential impacts on food security and biodiversity.

Finally, in the anaerobic conditions prevalent in landfills, biodegradable materials may undergo anaerobic degradation, producing methane, a potent greenhouse gas that contributes to climate change.

The Most Important Characteristics for Environmental Sustainability

Considering the research, the most important characteristic of a biodegradable material for environmental sustainability is its ability to achieve complete mineralization across diverse environmental conditions.

While other factors such as rapid degradation rates and sustainable sourcing are undoubtedly important, a material that fully breaks down into non-toxic, naturally occurring substances (carbon dioxide, water, biomass, and minerals) without leaving harmful residues or microplastics is paramount for mitigating pollution.

Materials that can biodegrade effectively in a variety of common disposal environments, such as soil, marine environments, home compost, and industrial compost, are preferable to those requiring very specific, controlled conditions. This adaptability reduces the likelihood of materials persisting as pollutants in unintended environments.

While rapid degradation rates are beneficial in preventing short- to medium-term waste accumulation, complete mineralization ensures long-term environmental safety. Sustainable sourcing and production of biodegradable materials, particularly bioplastics, are also critical to minimize their overall environmental footprint, considering factors like land use, water consumption, and greenhouse gas emissions.

Furthermore, biodegradable materials should be free of harmful additives and should break down into environmentally benign substances, ensuring no negative impact on ecosystems or human health. Ideally, these materials should also be compatible with existing waste management systems, or the development of appropriate separate infrastructure should be prioritized to manage them effectively.

Conclusion

In conclusion, the question of what makes a material biodegradable is multifaceted, involving a complex interplay of chemical and structural characteristics of the material itself, the environmental conditions it encounters, and the activity of diverse microbial communities.

Understanding these various factors is crucial for accurately assessing the biodegradability of a material and its potential environmental impact. While biodegradable materials offer a promising avenue for reducing the escalating problem of plastic waste and pollution, their effectiveness is contingent upon their ability to fully mineralize across a range of realistic disposal scenarios.

Ongoing research and development in this field are essential to create innovative biodegradable materials that not only break down effectively and safely but are also sustainably sourced and compatible with existing or emerging waste management infrastructures.